Prime Underwater Welding (PUW) provides specialized underwater welding and cutting services for offshore platforms, subsea pipelines, ports, ship repair and industrial onshore environments. Our teams combine hyperbaric dry welding expertise, wet welding capability, saturation diving and unmanned systems to deliver safe, high-quality solutions for complex marine and submerged repair projects.

Our commitment to safety, quality, and reliability makes us the preferred choice for complex underwater welding projects worldwide.

Our welder-divers are certified by leading organizations like AWS, IMCA, and ADCI.

We adhere to strict safety protocols with regular equipment checks and emergency response training.

State-of-the-art equipment including water-resistant electrodes and surface-supplied diving gear.

Wet welding reduces the need for expensive dry-docking or cofferdams, saving time and money.

Serving clients worldwide, from local harbors to deep-sea oil platforms.

Our streamlined approach ensures quality, safety, and efficiency from initial inquiry to project completion.

Submit photos, ROV footage and site coordinates. We perform initial feasibility, risk and logistics assessment.

Detailed scope, method statements, WPS and risk assessments. Mobilization plan and HSE documentation.

Equipment mobilization, vessel interface, permits and client briefings.

Supervisor-led operations, ongoing QA/QC and client communication.

NDT results, weld records, lift certificates, and final report.

We provide site-specific quotes that account for all project variables. Our transparent approach includes fixed-price options for discrete scopes and day-rate for open-ended campaigns.

For discrete scopes with well-defined requirements and deliverables.

For open-ended campaigns requiring flexible scheduling and scope adjustments.

Standby divers, extended ROV time, and third-party NDT services available.

PUW provides a comprehensive range of services to support marine and offshore industries. Our expertise ensures that your underwater structures remain safe, functional, and durable.

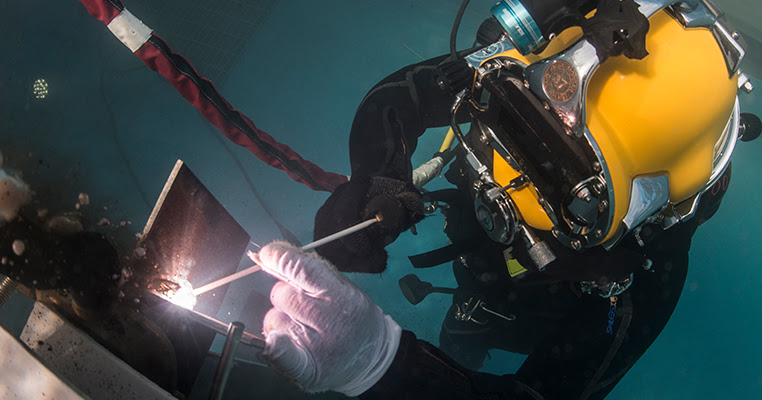

Wet welding is performed directly in water using specialized waterproof electrodes. This cost-effective and versatile method is ideal for quick repairs and projects where time and budget are critical. Our team uses Shielded Metal Arc Welding (SMAW) and Flux-Cored Arc Welding (FCAW) to create strong welds despite challenges like water pressure, poor visibility, and rapid cooling.

Temporary repairs, ship hull maintenance, pipeline patches, and sacrificial anode installation.

Fast, cost-effective, and adaptable to various underwater conditions.

We mitigate challenges like hydrogen embrittlement, porosity, and rapid cooling through advanced techniques and specialized electrodes.

Dry welding, or hyperbaric welding, is performed inside a sealed, pressurized chamber filled with a gas mixture to create a dry environment. This method delivers superior weld quality, making it ideal for critical applications requiring high strength and precision.

Permanent repairs on offshore oil platforms, pipelines, and structural components of ships and bridges.

Higher weld quality, reduced risk of defects, and compatibility with advanced techniques like GTAW.

PUW optimizes efficiency to balance quality and budget, despite higher cost and longer setup time.

Fast, cost-effective welding performed directly in water using specialized waterproof electrodes for quick repairs.

Superior quality welding performed in sealed, pressurized chambers for critical permanent repairs.

Comprehensive non-destructive testing and inspection services compliant with AWS D3.6M:2017 standards.

Complete vessel maintenance and repair services without the need for dry-docking.

Specialized maintenance services for offshore energy infrastructure in harsh marine environments.

Repair and reinforcement services for critical coastal and marine structures.

Specialized cutting and welding services for salvage operations and structure dismantling.

Tailored engineering solutions with custom WPS development and ABS-approved procedures.

Complete marine construction services from ship repairs to offshore platforms and coastal infrastructure.

Certified and compliant with industry-leading standards for underwater welding and marine operations

Contact our expert team for a comprehensive assessment of your underwater welding needs. We're available 24/7 for emergency response.